With the highest standards in both personnel training and equipment, we can assure our customers that each and every inspection is conducted to not only meet but exceed the stringent specifications and industry requirements for this service.

With the highest standards in both personnel training and equipment, we can assure our customers that each and every inspection is conducted to not only meet but exceed the stringent specifications and industry requirements for this service.

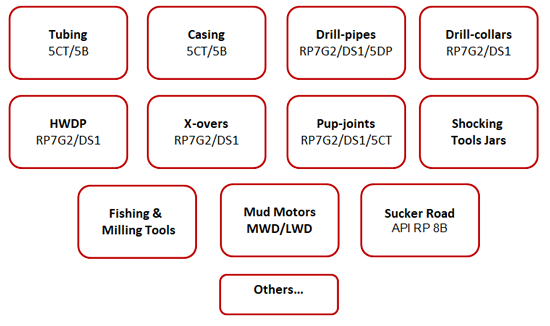

Our services cover a wide range of OCTG Integrity checks designed to identify possible defects on your Drill Stem which are the main causes of down-hole failures.

Through extensive field activities and research our Engineers having acquired a minimum of Level II SNT on relevant NDT techniques, in compliance to SNT TC 1A, prove to be the best in execution ensuring full adherence to regulatory standards; API RP 7G, NS-2, DS-1 BHA and Drill Pipe Inspections up to category 5.

Drill Pipe inspection as per API/DS 1/NS2 Standards:

• Full Body EMI 2.3/8” – 6.5/8”

• UT Shear wave & MPI Inspection on slip and upset area

• UT Thickness Gauging

• Black light connection Inspection

• Visual & Dimensional Inspection

• Heat check Inspection

• EMI

BHA/Specialty Tools inspection as per API/DS 1/NS2 / Client and OEM Procedures:

METS provide BHA Inspections on any drilling component used in the industry

Bottom Hole Assembly otherwise known as BHA inspections are carried out as per latest editions of DS-1 Cat 3-5 and API RP 7G-2. BHA inspections services include:

• Full Length MPI / LPT

• Black light connection Inspection

• Visual & Dimensional Inspection

• Heat check Inspection

• Elevator & Slip area Inspection

Inspection of Casing/Tubing in accordance with API Spec 5CT, API RP 5A5, 5C1, / OEM procedures:

• Visual inspection to include OD and ID surface condition, straightness, visual thread inspection.

• Full length drifting.

• Special end area inspection.

• Electromagnetic inspection using four function units to identify Transverse, Longitudinal,

Wall monitoring and Grade verification.

• Removal and replacement of API couplings

Bucking machine (Coupling Removal) is clamping mechanism with die applicable to different range from 2 7/8 – 7” casing/ conform to API standard.

Having manual reversing valve to operate clamp and rotate the screwed fittings, to achieve the makeup and breakout. 3 Different manual speed gear control